Authenticity check for electronic components

Trust is good, control is better

Authenticity testing for components such as integrated circuits

The global chip shortage from 2021 to 2023 led to an enormous increase in counterfeit semiconductors, which – as you are no doubt aware – poses significant risks to the entire supply chain.

The lack of genuine components, coupled with strict time-to-market requirements, created the perfect environment for component counterfeiters. They have simultaneously become increasingly sophisticated and now use advanced technologies to create near-perfect replicas. To counter this growing threat, comprehensive testing capabilities are essential to ensure the authenticity and functionality of procured semiconductors, as well as other electronic components.

These are the risks behind counterfeit semiconductors

Security risks

In safety-critical applications, faulty counterfeit ICs can pose a significant threat and jeopardize the safety of users and devices.

System malfunctions

Counterfeit ICs may not meet performance specifications, which can lead to unexpected system behavior and potential failures.

Shortened service life

Counterfeits often use inferior components, which leads to a shorter service life and higher maintenance costs.

Theft of intellectual property

Counterfeiting undermines the intellectual property rights of legitimate IC designers and hampers innovation and growth.

Security gaps

Malicious actors can embed hidden functions in fake ICs that create security vulnerabilities and potential backdoors for unauthorized access.

How we check

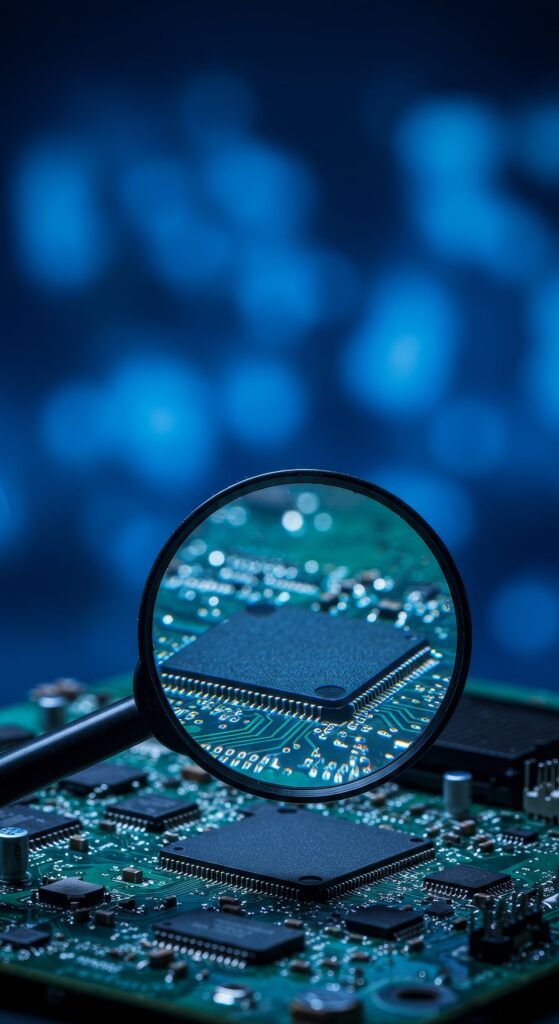

Physical inspection

Optical and visual inspections with manual and high-resolution camera systems (up to 1000x magnification) carefully examine housings and chips for signs of tampering or irregularities and identify potential physical markers of counterfeit parts.

Electrical tests

Functional tests with state-of-the-art equipment check the electrical properties of the semiconductor based on the manufacturer's specifications. This ensures that the part functions within the specified parameters and works as expected in your application.

Non-destructive X-ray analysis

This technique provides a comprehensive understanding of the inner workings of a component. Other methods such as scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDX) provide additional information. SEM provides high-resolution images of the surface of the component, while EDX enables elemental analysis that reveals the materials used.

Component opening

In some cases, decapsulation (exposure of the silicon chip) may be required to gain access to the internal components for this type of analysis. This is typically carried out on selected components (e.g. one part per date code and/or batch) in order to check the manufacturer's unique identification directly on the chip.

Programming validation (if applicable)

If component programming (or programming with test patterns) is requested, SEMITRON can check the integrity of the loaded firmware or code against the original specifications. In addition, a uniquely assigned and unchangeable manufacturer ID stored in the component is checked via the so-called ID check.

Authenticity testing of components at SEMITRON

We place great importance on trust and the integrity of the components in your supply chain. Our advanced test house goes beyond simple visual inspections and uses a multi-step authentication process for your components. This comprehensive approach minimizes the risk of counterfeiting and guarantees genuine components that can be seamlessly integrated into your production line.

Authenticity tests based on the AS6081 standard are geared towards safety-critical applications such as aerospace or medical technology. We are in close contact with our customers and always keep them informed of results and findings so that relevant decisions can be made at any time. This avoids unnecessary costs and loss of time.

By implementing the following strict authentication methods, we protect your production line from counterfeit components, ensuring trust and reliability.

- Optical and visual inspection of the general condition

- Dimensional accuracy test

- Solvent test on three components

- Chemical opening on two components

- Documentation of internal labeling

- Comparison with Golden Sample (original manufacturer component)

- Test report in electronic form

- Optical and visual inspection of the general condition

- Dimensional accuracy test

- Solvent test on three components per data code

- X-ray examination of 45 pieces

- Scanning electron microscopy on three pieces

- Chemical opening of three components

- Documentation of internal labeling

- Comparison with Golden Sample (original manufacturer component)

- Test report in electronic form

Do you want to be on the safe side when it comes to the authenticity of components?

Three steps for certainty

Frequently asked questions about authentication

Are authenticity tests necessary for components purchased through your sales department?

Authenticity checks are not required for devices purchased through our distribution services. However, we strongly recommend these services for devices purchased through unauthorized vendors and third parties, such as brokers.

Which services are frequently requested together with authenticity checks?

Most of the requests we receive together with authenticity checks concern packaging services for an extended service life.

How long does a typical authenticity check take?

This will vary depending on your specific needs and volumes. Please indicate your time frame in your initial request so that we can do our best to meet it.

More than just authentication

SEMITRON’s unique value lies in its combined expertise in distribution and test house services. As an authorized distributor, we offer a wide range of components from leading manufacturers. But we don’t just supply components. Our state-of-the-art facilities and test house services ensure that your components work perfectly in your specific application. Throughout the process, you benefit from the extensive knowledge and support of our team.

SEMITRON’s test house offers a variety of services beyond authenticity testing. We can perform various tests to ensure the quality and functionality of your electronic components. These include optical/visual inspections, component analysis and thermal testing. In addition, we offer services such as taping, rework and mechanical modifications to meet your specific project requirements.

Do you want to be on the safe side when it comes to the authenticity of components?

Three steps for certainty

Request initial consultation

Analysis of your requirements

Quote & execution