Did you know optocouplers are not needed for isolated DC-DC? Now you can simplify your design and reduce solution size with no-opto solutions.

From time to time, there is a need for an isolated DC-DC solution, either for safety reasons or to ensure proper operation in a complex system. Traditional isolated solutions use either optocouplers and additional circuitry, or complex transformer designs to form a feedback loop across the isolation barrier to regulate the output voltage. The extra components make complicated and large designs. The optocouplers degrade over time, reducing system reliability. Furthermore, end equipment form factor is shrinking, leaving limited space for power supply, and adding thermal management challenges. The system engineer must overcome all these challenges when starting a new isolated DC-DC design. The system engineer needs a small, low-cost, highly reliable, and easy-to-design solution.

Fortunately, there are new no-opto flyback solutions that eliminate the optocouplers, associated feedback circuitry, and the need for third transformer winding. The new solutions also provide new benchmarks for output voltage accuracy.

Many power systems in a variety of industries such as factory automation, building automation, e-mobility, automotive, avionics, medical, commercial, and others employ isolated DC-DC converters for one or more of the following three reasons:

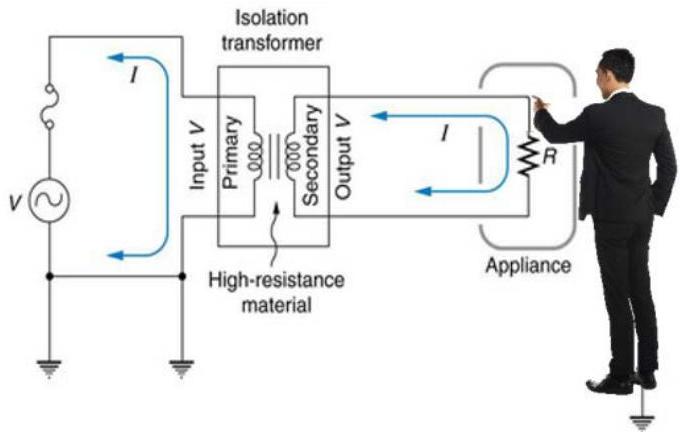

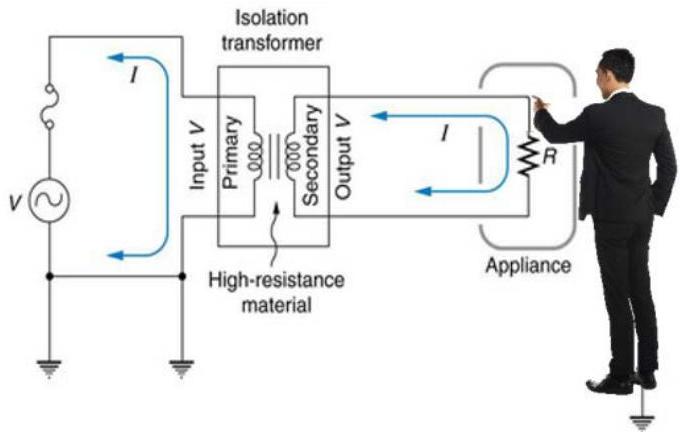

Safety: To prevent current surges from damaging equipment and protect humans from the main power source. Figure 1 illustrates a power system with the main power source isolated from the secondary side, where a human operator can have physical contact with it. Without proper safety isolation, a lightning strike could send a very high voltage surge through the equipment to the operator and ground. This is mostly lethal. The isolation barrier here routes the dangerous surge energy back to the primary ground, thus avoiding it passing through the operator.

Figure 1. Isolation for safety.

Avoid Ground Loops: In a large or complex system, grounding potential differences exist at different areas. Isolation is used here to avoid disruptive ground loops, and also isolate digital noise from the precision analog system.

Figure 2. Isolation to avoid ground loop.

Level Shifting: Occasionally, a system with a mixture of many power rails uses isolated DC-DC to generate multiple isolated positive and/or negative output voltages.

Figure 3. Isolation for level shifting.

Figure 4 illustrates a traditional isolated DC-DC converter. The solution uses an optocoupler, error amplifier, and a voltage reference to form a feedback loop across the isolation barrier. In this implementation, the output voltage is sensed by an error amplifier, then compared to a voltage reference. The information is passed across the isolation barrier through an optocoupler to the primary side, where the control circuit modulates the power stage to regulate the output voltage.

Figure 4. Traditional isolated DC-DC converter using optocoupler and associated feedback circuitry.

This solution serves its purpose very well until the equipment shrinks and leaves little room to fit it. The optocoupler, error amplifier, and voltage reference circuit have 12 components, which substantially add to the total design component count and take up large board space (Figure 5). Naturally, there comes a quest to eliminate this circuitry.

Figure 5. Traditional feedback circuit using optocoupler, error amplifier, and a voltage reference.

The optocoupler faces another major issue: its performance varies with temperature and degrades over time, which can cause reliability issues for certain applications. Figure 6 shows a typical optocoupler’s Current Transfer Ratio (CTR) that varies 270% over the -60 degrees C to 120 degrees C temperature range. On top of that, this CTR drops 30% to 40% over time.

Figure 6. Optocoupler collector current vs. ambient temperature.

Primary side control topology: One way to eliminate the optocoupler is to employ the primary side control method. In this scheme, a third winding on the power isolation transformer is used to measure the output voltage indirectly during the OFF cycle. Figure 7 illustrates such a circuit. The reflected voltage, V_W is proportional to the output voltage following the equation:

V_W = (V_O + V_F) x N_a / N_S

where V_O is the output voltage, V_F is the output rectifier diode voltage drop, N_a is the third winding number of turns, and N_S is the secondary winding number of turns.

Figure 7. Primary side control using third transformer winding.

While this method effectively eliminates the optocoupler, it creates a new set of issues:

This primary side control method offers poor output voltage regulation and thus is not practical in many applications, forcing the designer to use a post regulator, which adds even more, cost and increases the total solution size.

No-Opto Flyback Topology: The no-opto flyback DC-DC is a variation of the primary side control method. It eliminates issue (a) mentioned above by sensing the primary side voltage directly, thus not requiring a third winding in the power transformer. This improvement significantly reduces the complexity in the transformer design and construction and PCB layout. Figure 8 describes this topology.

Figure 8. No-opto flyback circuit.

The reflected voltage, V_P is proportional to the output voltage following the equation:

V_P = (V_O + V_F) x N_P / N_S

where V_O is the output voltage, V_F is the output rectifier diode voltage drop, N_P is the primary winding number of turns, and N_S is the secondary winding number of turns.

No-opto flyback topology is not new, and it still suffers from the two remaining issues (b) and (c) mentioned above. In this case, (c) applies to the leakage inductance ringing on V_P instead of V_W. Poor output voltage regulation remains the most technical challenge for this no-opto flyback circuit.

Thankfully, recent circuit design advancement and proprietary techniques have improved this bottleneck in a big way. Let us take a closer look!

Conquering Poor Output Voltage Regulation Issue: Figure 9 shows a new product from Maxim Integrated, the MAX17690, which provides a no-opto flyback isolated DC-DC converter solution with +/- 5% output voltage regulation.

Figure 9. No-opto flyback circuit achieving new output voltage regulation benchmark.

To combat the sensed output voltage reading error, the MAX17690 samples the reflected voltage when the secondary current, I_SEC, is low. This technique alleviates the diode voltage drop variation due to output loading. The IC also has a provision to compensate for the diode voltage and its variation due to temperature. It also uses advanced technique to filter out leakage inductance ringing. Altogether, this IC brings a new output voltage regulation benchmark to the no-opto flyback topology.

Figure 10 shows a variation, MAX17691, that also integrates the power FET and current-sensing element, thus requiring very few external components to complete a whole circuit. It truly offers a high-performance isolated DC-DC converter solution in its simplest form.

Figure 10. Highly integrated no-opto flyback solution.

Both MAX17690 and MAX17691 achieve very good output voltage regulation. Figure 11 shows their performance over temperature, line, and load variations.

Figure 11. MAX17690/91 output voltage regulation. A new benchmark!

Shrinking equipment and board space render ineffective large, traditional isolated DC-DC converters that use optocouplers for feedback loop. The optocoupler performance varies with temperature and degrades over time, which is another hindrance. The no-opto flyback topology is simpler, requires fewer external components, and is naturally a better choice. New advancement in design techniques largely improve output voltage regulation, making the no-opto flyback DC-DC converter practical and a proper choice for isolated power supply applications.

By Thong ‚Anthony‘ Huynh, Principal Member of the Technical Staff, Industrial and Healthcare Business Unit, Maxim Integrated.